Executive Summary

Nicotinamide Adenine Dinucleotide (NADH) serves as the primary electron carrier in cellular respiration, acting as the bridge between metabolic breakdown and energy production. For manufacturers in the nutraceutical and pharmaceutical industries, understanding the biochemical mechanism of NADH is critical for formulating effective mitochondrial support products. This technical guide explores the role of NADH in the Electron Transport Chain (ETC), its impact on ATP synthesis, and why sourcing high-purity NADH powder from a verified NADH manufacturer is essential for maintaining product efficacy and shelf-life stability.

The Metabolic Engine: How NADH Powers Cellular Respiration

Cellular respiration is the process by which biochemical energy from nutrients is converted into adenosine triphosphate (ATP). NADH, the reduced form of NAD+, plays a non-negotiable role in this multi-stage process. As a business professional in the health science sector, recognizing the “redox” (reduction-oxidation) potential of your NADH raw material is key to evaluating the quality of your end products.

1. The Glycolysis and Krebs Cycle Phase

During glycolysis and the Citric Acid (Krebs) Cycle, NAD+ is reduced to NADH by picking up high-energy electrons from glucose derivatives. At this stage, NADH acts as a temporary “battery,” storing potential energy to be used later in the mitochondria.

2. The Electron Transport Chain (ETC)

The most critical role of NADH occurs in the inner mitochondrial membrane. Here, NADH delivers its electrons to Complex I (NADH-ubiquinone oxidoreductase). This “handoff” initiates a flow of electrons that powers the pumping of protons across the membrane, creating an electrochemical gradient.

3. ATP Synthesis via Oxidative Phosphorylation

The energy stored in the proton gradient is finally used by ATP synthase to produce ATP. Without a consistent supply of high-quality NADH, the ETC would stall, leading to a significant drop in cellular energy output and an increase in oxidative stress.

Why Quality Standards Matter for NADH Raw Material

For B2B buyers and formulators, the challenge is not just finding NADH, but finding a stabilized form. NADH is notoriously sensitive to light, moisture, and temperature.

-

Purity and Potency: As a dedicated NADH manufacturer, we understand that even minor impurities can catalyze the degradation of the powder, turning it back into NAD+ before it reaches the consumer.

-

Bioavailability: The manufacturing process must ensure that the NADH powder remains biologically active. This requires rigorous climate-controlled production and specialized stabilization techniques.

-

Compliance: Professional-grade formulations require raw materials backed by ISO, GMP, and third-party testing to ensure they meet global safety standards for nutraceutical and pharmaceutical use.

B2B Procurement: Selecting a Reliable NADH Manufacturer

When sourcing NADH raw material for industrial or R&D use, the stability of your supply chain is as important as the chemistry itself. A reliable partner should provide:

-

Consistent Particle Size: Ensuring easy blending and encapsulation.

-

Stable Lead Times: Minimizing production delays for your manufacturing runs.

-

Full Traceability: Providing a clear audit trail from raw synthesis to the final packaged powder.

Frequently Asked Questions (FAQ)

Q: Why is NADH preferred over NAD+ in certain energy supplements? A: While both are vital, NADH is the “ready-to-use” electron donor. In the context of cellular respiration, it directly feeds Complex I of the electron transport chain, making it a popular choice for targeted mitochondrial support formulations.

Q: How should bulk NADH powder be stored to prevent degradation? A: NADH should be stored in a cool, dry place, ideally at temperatures below 4°C, and protected from light in airtight containers. As a manufacturer, we provide specific handling protocols to ensure the material remains potent during transit and storage.

Q: Can NADH be used in liquid formulations? A: NADH is highly unstable in aqueous solutions. For B2B applications, it is most commonly used in dry formats like capsules, tablets, or stabilized sublingual powders.

Conclusion

NADH is the linchpin of cellular bioenergetics. Its ability to donate electrons within the mitochondria makes it an indispensable ingredient for the next generation of metabolic and longevity products. For businesses, the value lies in the intersection of biological efficacy and material stability. By choosing a partner that masters the complex synthesis and stabilization of NADH powder, you ensure that your products deliver the energy-boosting results they promise.

About Gothink Biology

Shenzhen Gothink Technology and Services Co., Ltd. (Gothink Technology) is a premier manufacturer and global supplier of functional raw materials based in China. We specialize in cutting-edge synthetic biology to produce high-purity ingredients for the nutraceutical, dietary supplement, and pharmaceutical industries.

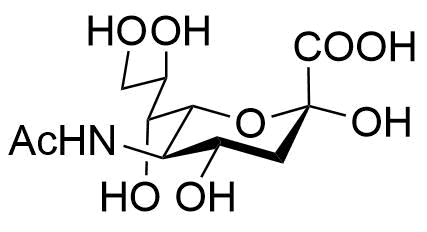

Our core expertise lies in the production of Coenzymes (NMN, NADH, NAD+, NADP), Human Milk Oligosaccharides (HMOs), and Glucosamine derivatives. Led by a world-class scientific team trained in the US and UK, Gothink Biotech manages over 2,000 customized formulations annually. Our facilities are held to the highest global standards, with certifications including ISO 9001, ISO 22000, GMP, SGS, NSF, and Halal, ensuring complete traceability and trust for our global B2B partners.